Blog

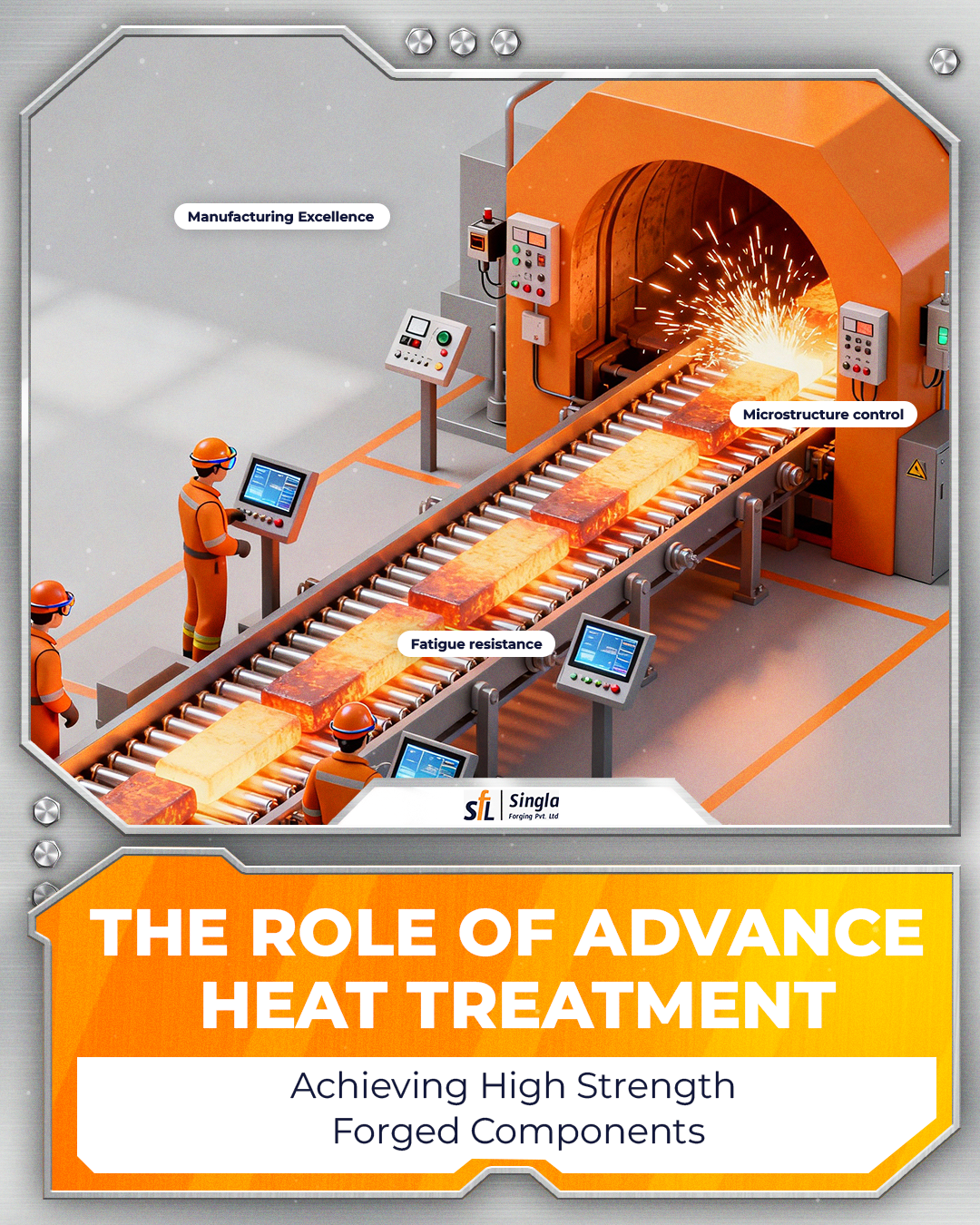

The Role of Advanced Heat Treatment in High-Strength Forged Components

Heat treatment is one of the most important steps in achieving high-strength forged components. While forging shapes and compresses the metal, heat treatment enhances its internal structure, improves durability, and ensures consistent performance in demanding applications. For industries like automotive, agriculture, heavy machinery, and construction, this process is essential for delivering components that can withstand extreme loads and wear.

Why Heat Treatment Is Important After Forging

Forging naturally strengthens metal by aligning grain flow, but it may still leave internal stresses or uneven hardness. Heat treatment corrects these issues by refining the microstructure and improving key properties such as:

- Strength and hardness

- Toughness and shock resistance

- Wear and fatigue resistance

- Dimensional stability

This ensures every forged part performs reliably under real working conditions.

Key Heat Treatment Methods for Forged Components

1. Quenching & Tempering

A high-strength combination.

- Quenching hardens the metal rapidly.

- Tempering restores toughness and reduces brittleness.

Ideal for shafts, gears, and critical load-bearing parts.

2. Normalizing

Air cooling after heating creates a uniform grain structure.

Benefits: better machinability, balanced strength, and consistent performance.

3. Annealing

Softens the material and relieves stress.

Used to improve machinability and prepare metal for further processing.

4. Case Hardening

Processes like carburizing and nitriding harden the surface while keeping the core tough.

Perfect for components that require high wear resistance.

Benefits of Advanced Heat Treatment

- Higher strength and load-carrying capacity

- Increased impact and fatigue resistance

- Improved wear performance

- Enhanced stability during machining

- Custom mechanical properties for specific applications

These advantages make heat treatment essential for producing high-performance forged components.

Conclusion

Advanced heat treatment transforms forged metal into a high-strength, long-lasting, and reliable component. By optimizing hardness, toughness, and structural integrity, heat-treated forgings deliver superior performance across industries. For manufacturers like Singla Forging, combining precision forging with modern heat-treatment processes ensures components that meet today’s highest standards.