Blog

Precision-Engineered Two-Wheeler Parts: Shaping Tomorrow’s Mobility

In today’s rapidly changing world of transportation, two-wheelers remain essential for efficient and adaptable urban mobility. As the sector shifts toward smarter and greener solutions, the spotlight

increasingly falls on the importance of high-quality components. Companies like Singla Forging Pvt. Ltd. are at the forefront, enabling the evolution of mobility through a commitment to precision engineering, reliable manufacturing, and innovative thinking.

Bridging Innovation and Manufacturing

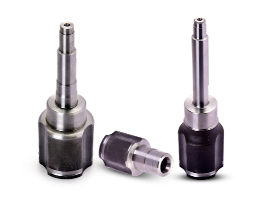

With over 30 years of experience, Singla Forging has established itself as a key producer of precise automotive parts. Operating through nine modern production plants situated strategically near automotive clusters, the company ensures effective coordination and uninterrupted manufacturing workflows. The facilities feature advanced CNC machinery, sophisticated heat-treatment systems, and integrated assembly lines, all designed to uphold the highest standards in part durability and precision. This setup enables end to-end production, from raw material processing to final assembly, reinforcing Singla’s status for delivering robust, custom solutions.

Commitment to Quality and Process Excellence

At its core, Singla Forging prioritizes a continuous improvement culture, drawing on global quality frameworks such as Kaizen, 5S, and Six Sigma to guarantee both product reliability and process efficiency. Stringent inspection methods—including dimensional and material integrity tests—are used to ensure every component adheres to demanding requirements before entering the market.

Leading in Technological Advancement

Anticipating future demands is central to the company’s approach. Singla’s development teams leverage modern design tools and flexible manufacturing processes to build parts that not only satisfy current specifications but also keep pace with changing mobility trends. This proactive mindset enables effective customization and adaptation for the next generation of two-wheelers.

Industry Trends Driving Change

The two-wheeler industry worldwide is experiencing several transformational trends that influence component design and manufacturing:

Electrification and Localization

The rapid adoption of electric two-wheelers is intensifying the need for specialized parts, such as battery housings and lightweight drive systems. In India alone, the value of this component market is forecast to almost double between 2024 and 2033, aided by localization incentives and government policies.

Smart and Connected Technologies

Integration of digital features—like cloud-based battery monitoring, connectivity modules, and advanced rider interfaces—is becoming the norm, enabling manufacturers to deliver interactive, data-driven

experiences.

Design Optimization and Safety

Computer-aided engineering now plays a pivotal role in designing lighter, safer, and more efficient vehicles. Modern simulation tools support innovations in frame, suspension, and safety-related systems, driving the industry toward safer urban mobility.

Singla Forging’s Strategic Advantages

Within this competitive landscape, Singla Forging stands out by integrating fully coordinated production lines, rapid product development, and extensive quality controls across its multi-site operations. The company’s broad capabilities allow for quick adaptation to new demands, while its large-scale facilities maintain quality and consistency crucial for supporting the rise of electric and connected vehicles.

Conclusion

Precision automotive components are central to the ongoing transformation of urban mobility. Manufacturers like Singla Forging, with their blend of advanced technology, process excellence, and forward

thinking development, are enabling safer, smarter, and cleaner travel options for the future. Their integrated approach ensures that each part not only meets present-day requirements but also helps define what’s next in two-wheeler transportation.